For months a group of DUL staff including Mike Adamo and Molly Bragg from the Digital Production Center, Josh Sosin and Ryan Baumann from the Duke Collaboratory for Classics Computing, and myself have been discussing the potential use of multi-spectral imaging (MSI) in our work. This week, Mike Toth and Bill Christens-Berry of R.B. Toth Associates were on campus to facilitate two days of MSI imaging.

Day 1: An alternative to scanning mice eyes

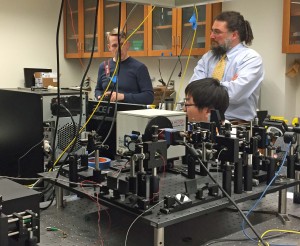

Mr. Toth’s sister, Dr. Cynthia Toth, is an ophthalmologist at the Duke Eye Center. She uses optical coherence tomography (OCT) to scan premature infants’ eyes to detect neurological and visual problems. Dr. Toth and Mr. Toth coordinated time with Dr. Sina Farsiu and his graduate student Guorong Li to image a few papyri from the David M. Rubenstein Rare Book and Manuscript Library. Dr. Farsiu uses OCT in his research. When he isn’t kindly imaging papyri, he is scanning mice eyes. Dr. Farsiu also coordinated time in Dr. Adam Wax’s lab in the Biomedical Engineering Department where we used their OCT scanner to image the papyri using a slightly different set up. Dr. Wax’s team is usually scanning rat esophagi and mice eyes, so a day with papyri was a bit out of their wheelhouse but everyone seemed to enjoy the collaboration. The Raleigh News & Observer was there as well and posted this story.

Mike Adamo from the DPC and I escorted the Rubenstein collection materials to the Duke Eye Center and the Biomedical Engineering lab. My role was to provide safe transportation across campus, and to handle the fragile items. Having researched OCT, I felt that this was a safe, non-destructive imaging technique for the papyri. It’s hard to say what the outcome of the OCT scanning will be, but it has potential to reveal hidden media, which is exciting to think about.

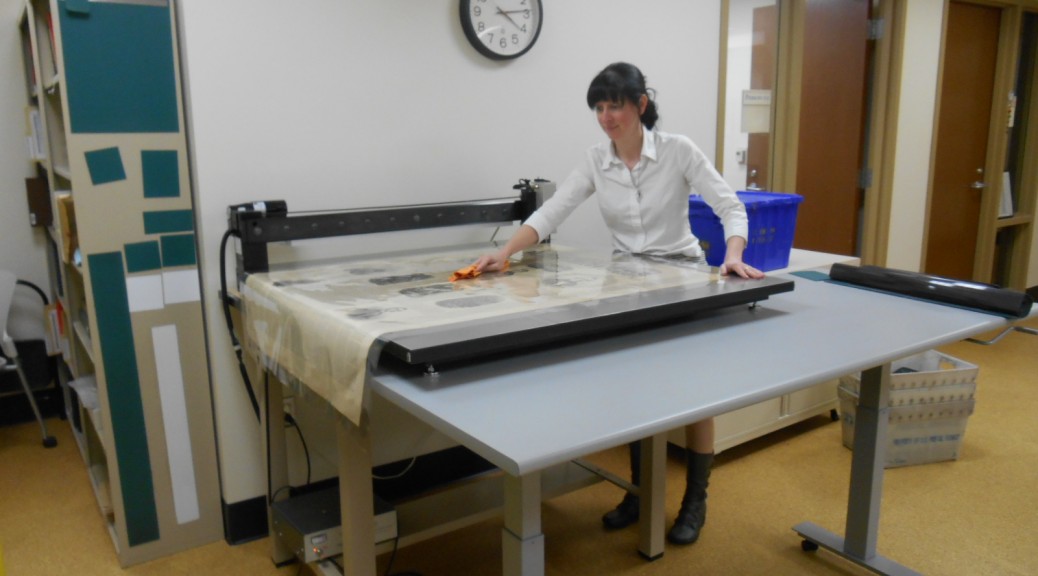

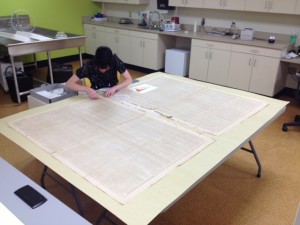

Day 2: MSI Scanning in DPC

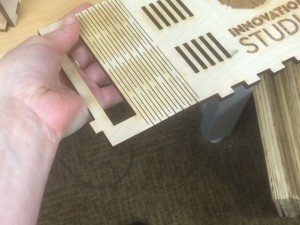

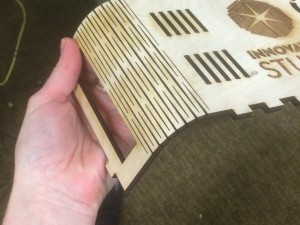

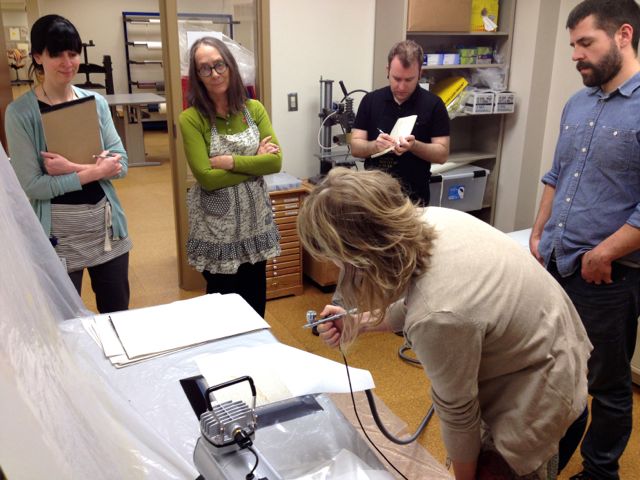

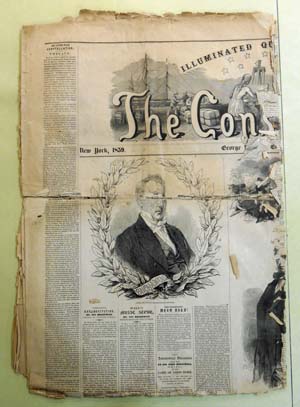

On Wednesday, Toth and Christens-Berry set up their MSI equipment in the DUL Digital Production Center. Their system scans at a variety of UV and IR wavelengths. The Library was interested in testing a range of problems to see what this system could reveal. The materials we scanned included several papyri with obscured text, two early Hebrew manuscripts whose writing is almost completely obscured by the condition of the gevil, a bound book with a Latin manuscript paste-down that is obscured by a previously adhered bookplate, and a Greek manuscript that was scraped and written over. All of these items present common problems for researchers using ancient texts.

|

|

Proof of Concept

The work that we did on Tuesday and Wednesday was meant to provide “proof of concept” for the conversations that must happen regarding funding, staffing, training, workflows and service expectations if the Library were to develop an MSI scanning workflow.

Conservation is excited about MSI for its potential to discover more about the materials we work on. Having the ability to image in both UV and IR would expand our knowledge of the materials, expose information we can’t see with the naked eye, and enable us to envision better treatments. I think we are all excited for its potential to provide access to materials that right now cannot be easily used or read, such as the Hebrew manuscripts and the hidden texts on the papyri cartonnage. We literally had a “Holy [Cow]” moment when we saw these materials give up their secrets. It gave me goosebumps.

Mike Adamo wrote a blog post for Bitstreams describing their side of this project.