Conservators can be a bit obsessive when it comes to hand tools. Not only must a tool be well suited to perform a specific task, but it must also be ergonomic. If a stock tool is not quite right for the job, I may modify it or just make the tool that I need from scratch. Making or adapting tools does not have to be time consuming or expensive, and some of my favorite tools are quite simple.

For example, I find myself doing a lot of lifting and scraping in my day-to-day work. Original binding material may need to be lifted or damaged paper may have small scarf tears that need to be manipulated. Scraping may be an effective method for mechanically removing accretions, desiccated adhesive, or old lining material. The following three examples are my favorite tools for these tasks, which I have either modified, fabricated, or purchased.

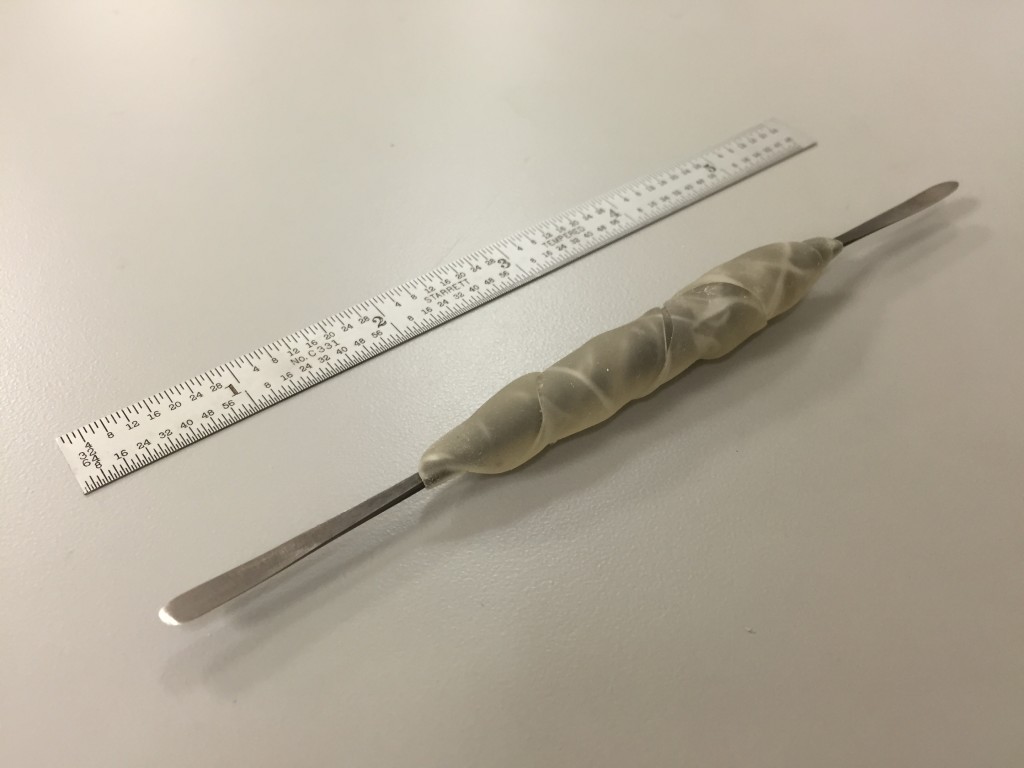

The Casselli 6 1/8″ micro-spatula is great for lifting very thin material, like paper. The size of the spatula ends and thin, flexible steel make it perfect for a lot of small tasks.

Two modifications have really improved the working properties of this tool for me: shaping the rounded edge and making the center handle thicker. I have left the pointy end of my spatula unmodified, but I added a single bevel to the rounded end with 3M micro-finishing film abrasive to make it more like a blade. This allows me to get the tool underneath very thin material. The unmodified octagonal handle is fine for quick work, but really becomes tiresome on the pads of my index finger and thumb after lengthy use. I used a common material known as Elastack (by Sutton Scientifics, Inc.) to increase the circumference of the handle and make it more comfortable to hold. Elastack is available in two levels of softness and is very quick to apply or re-wrap to adjust the shape of a tool.

The Casselli is not robust or sharp enough for lifting heavy material (such as leather), so for those tasks I will often switch to a lifting knife. I made this small lifting knife from a 1/2″ Starrett hacksaw blade a few years ago in a workshop with Jeff Peachey and use it just about every day.

The total time to make this tool was less than an hour and the material cost is quite low. After grinding the teeth off of the hacksaw blade and rough shaping the round edge using a belt sander, the final sharpening was done by hand. The handle is just thick horse butt leather cut to shape and adhered with PVA. Because the high-speed steel makes sharpening fairly quick, I find myself more likely to resharpen this knife than others in my collection made from harder steel.

A recent acquisition that I have been experimenting with lately is this micro-chisel made by Shanna Leino. With a bit of stropping, it is incredibly sharp and I find that it can do certain tasks better than a scalpel.

One method of mechanically removing a solid, brittle accretion is to press a blade vertically, very close to the edge of the layer and break it off (Ashley-Smith, 1992, p. 30). Of course there are many variables to consider on whether this is a safe or effective method to employ, but in cases where I have been able to use it, the micro-chisel works wonders. I suspect that it will also come in handy the next time I am creating a model of a wooden board binding, particularly for shaping the sewing support channels.

I really enjoy experimenting with different hand tools and applying simple modifications to improve them. What is your favorite hand tool?

Ashley-Smith, J. (1992). Science for conservators: Volume 2 cleaning. London: Museums and Galleries Commission.