This spring has been pretty busy and keep forgetting to post an update on “Large Marge“, our new standing press. She had been in storage for a while before arriving here and needed a bit of TLC before we could start using her. We also needed some help from our colleagues in Facilities to create a modification for the base.

After vacuuming off the cobwebs and giving all the parts a quick brushing, I wanted to address the rust that had started accumulating on the base and support rods.

The rust was pretty superficial, so I was able to remove it with steel wool. I applied a thin layer of Bowling Alley Wax to all of the surfaces to prevent further oxidation.

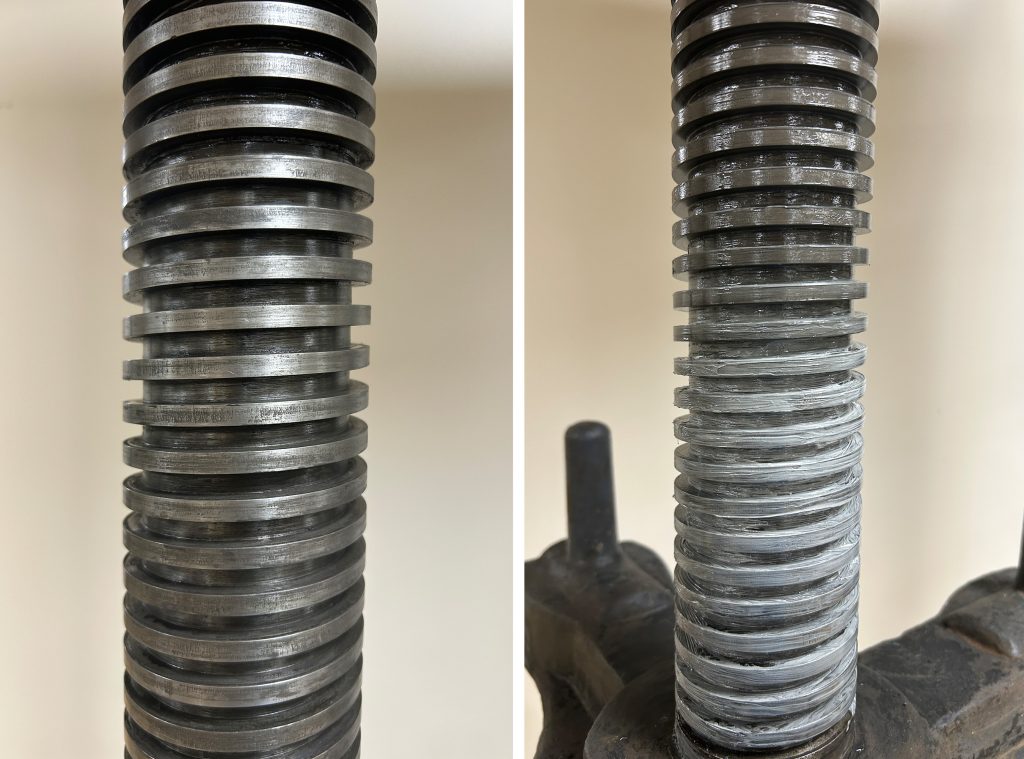

The next thing that needed addressing was lubricating the threads of the large screw. The grease inside the threaded flange was still functional, but all of the lubricant exposed to air had completely dried out. I found the easiest way to remove it was to scrape it off the threads with a micro-chisel.

Once the screw was clean, I added some new lithium grease and then raised and lowered the platen a couple of times to spread it across the threads evenly.

The most important addition to Marge was a modification to the base. These presses were designed for edition work with many books being stacked between pressboards and loaded in at once. This means that with the platen in its lowest position, there is still about 30″ of daylight between the base and platen. Since we are only pressing one item at a time, we needed to raise that bottom surface up.

Thankfully one of the carpenters in Duke’s Facilities Management Department was able to build a box that fits exactly inside the gap. The box is reinforced to withstand the full strength of the press, even when someone is using the extended arm to tighten it. An added bonus is that all of the pressboards can be stored inside.

Thankfully one of the carpenters in Duke’s Facilities Management Department was able to build a box that fits exactly inside the gap. The box is reinforced to withstand the full strength of the press, even when someone is using the extended arm to tighten it. An added bonus is that all of the pressboards can be stored inside.

I’m looking forward to putting this press to use, particularly for building clamshell boxes for folio and double folio-sized books. Books of that size are often very heavy and difficult to move around, so they can benefit from the added protection of a cloth-covered enclosure.